Talavera pottery is one of the most beautiful art forms in Mexico. Talavera Poblana, as it is now known, has set itself aside from the Talavera pottery of Spain, which began to be produced as early as the 13th century. This Majorca pottery, a combination of Moorish, Italian, and indigenous techniques, was introduced to Mexico by the Spanish at the beginning of the colonial period.

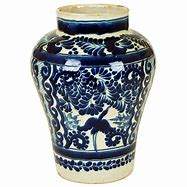

Dating back to the early 1500s, original Mexican Talavera pottery came only from San Pablo del Monte, Puebla, Atlixco, Cholula, and Tecali in the states of Tlaxcala and Puebla. These areas have the perfect natural clay for making the pottery. Originally, items were finished in cobalt blue and white. Later, yellow, black, green, orange, and mauve were used.

Products became popular because of the fine clay. Demand from churches and monasteries for tiles was very high in the states of Puebla and Tlaxcala, where the Talavera was produced. In the 17th century, standards and guides had been set and the quality of the work improved greatly. In Puebla, the “Golden Era” of Talavera pottery was between the years 1650 to 1750.

In the early 19th century after the War of Independence, the tradition suffered. There were fewer than eight workshops operating in Puebla.  Efforts by artists and collectors revived the craft in the early 1900s. Further efforts to promote the craft with new designs were implemented later in the century. For example, the ”Denominación de Origen de la Talavera” law was passed to protect authentic Talavera pieces made with the 16th century methods. Talavera is made from a mixture of only two sands, a dark and a light, to give it a rose color. It is formed on a potter’s wheel by hand, not poured. Two firings are required at an oven temperature of at least 800° C. Six color pigments are used to enhance the workmanship.

Efforts by artists and collectors revived the craft in the early 1900s. Further efforts to promote the craft with new designs were implemented later in the century. For example, the ”Denominación de Origen de la Talavera” law was passed to protect authentic Talavera pieces made with the 16th century methods. Talavera is made from a mixture of only two sands, a dark and a light, to give it a rose color. It is formed on a potter’s wheel by hand, not poured. Two firings are required at an oven temperature of at least 800° C. Six color pigments are used to enhance the workmanship.

The Mexican Talavera Regulatory Council regulates the production of Talavera and restricts the use of the term to the items produced within the designated zone of Puebla. Nine certified workshops must pass two inspections per year to insure their process remains authentic. The inspectors also ensure that the glaze contains acceptable levels of lead and cadmium (2.5 parts/million of lead, .25 parts/million of cadmium).

Certified Talavera pieces bear the signature of the potter, the logo of the workshop, and the special hologram that shows the piece to be authentic. Only pieces from workshops that meet the standards are certified. Today fewer than twenty certified workshops are producing authentic pottery.

Leave a Reply